2024 EFRW Transformer

Components

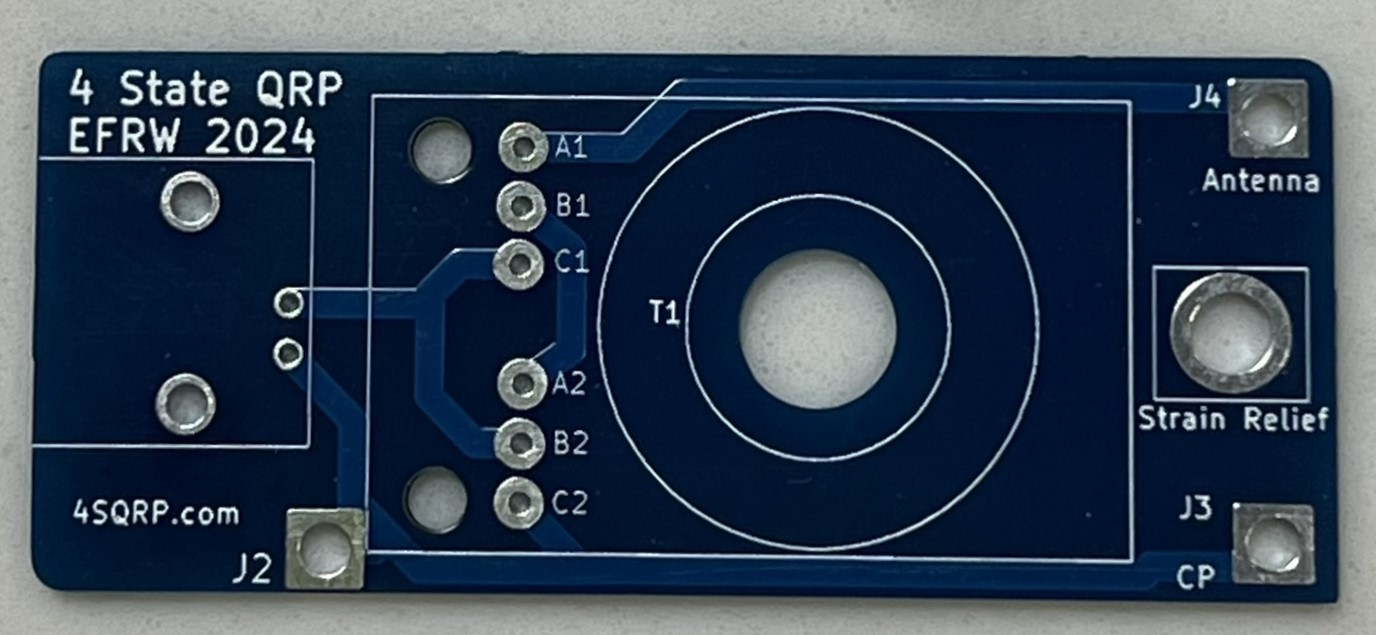

- Bare PCB

- BNC connector

- Toroid T94-6

- 48" of 22AWG enamel coated wire

Tools

- flush cutters

- mini pliers

- utility knife

- ruler

- soldering iron, set to 350C

- spudger

- heat safe work surface (or board holder)

Instructions

Winding the toroid

We will construct a 12 Turn trifilar winding.

- Cut the enamel coated wire into 3 equal lengths of 16". These will be your winding wires.

- Take one length of wire, bend it in half to create a U shape.

- Hook this U shape over the toroid to start your winding.

- Wind each half of the wire around the toroid.

- Each pass of the wire through the toroid counts as 1 turn.

- You want 12 turns around the toroid with each wire.

- Be careful to not scrape off enamel coating when pulling the wire through the toroid.

- Press the wire tightly against the toroid.

- Repeat the above process for each of the two remaining wires.

- These wires should be wound between the turns of the previous wire(s).

- Do not cross the wires over each other. Each wire should have its own separate, parallel path around the toroid.

- Once all wires are wound, double-check your work. You should have 12 turns per wire, for a total of 36 turns.

Testing and soldering the toroid

Construction and testing:

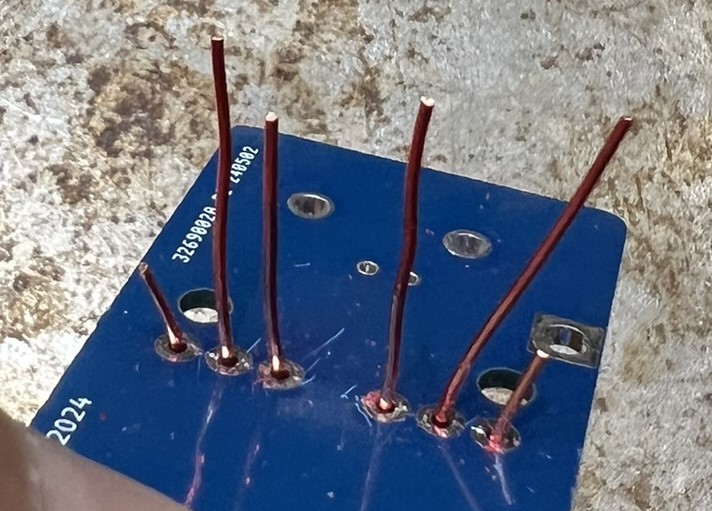

- Feed the ends of the wires through A1, B1, C1, and A2, B2, C2 on the other end. DO NOT TRIM the wires yet!

- Remove a bit of the enamel from the ends of the wire. Where the wire is NOT in contact with the through hole it is passing through.

- Use an ohm meter to check that you have continuity between A1 and A2, B1 and B2, and C1 and C2.

- Now, carefully trim the wires, and remove enamel so that the wires will contact the through holes.

- Solder connections.

- Test continuity from BNC center to J4 - Antenna.

- Test continuity from BNC ground to C1 and J3 - CP.

Note: the spudger can be used to evenly space the wire around the toroid.

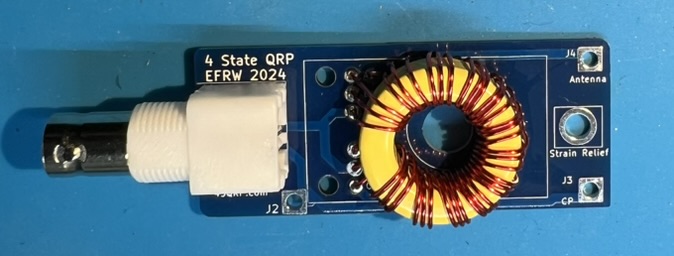

BNC

- Solder the BNC to the board.

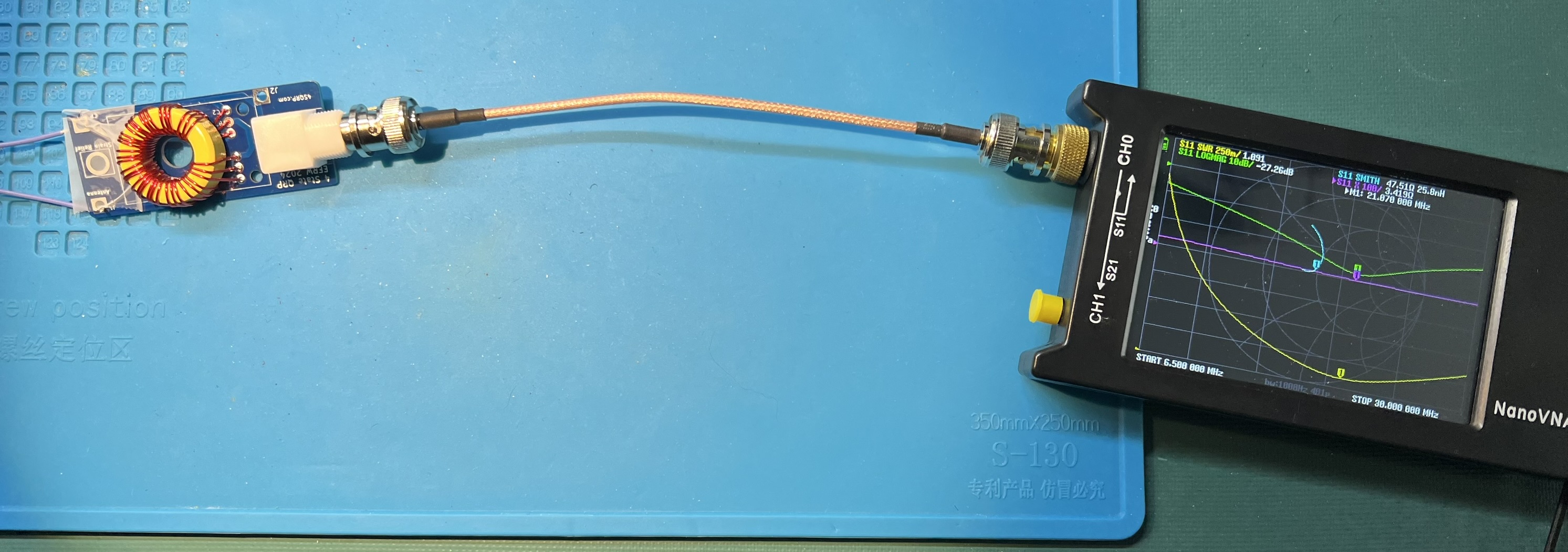

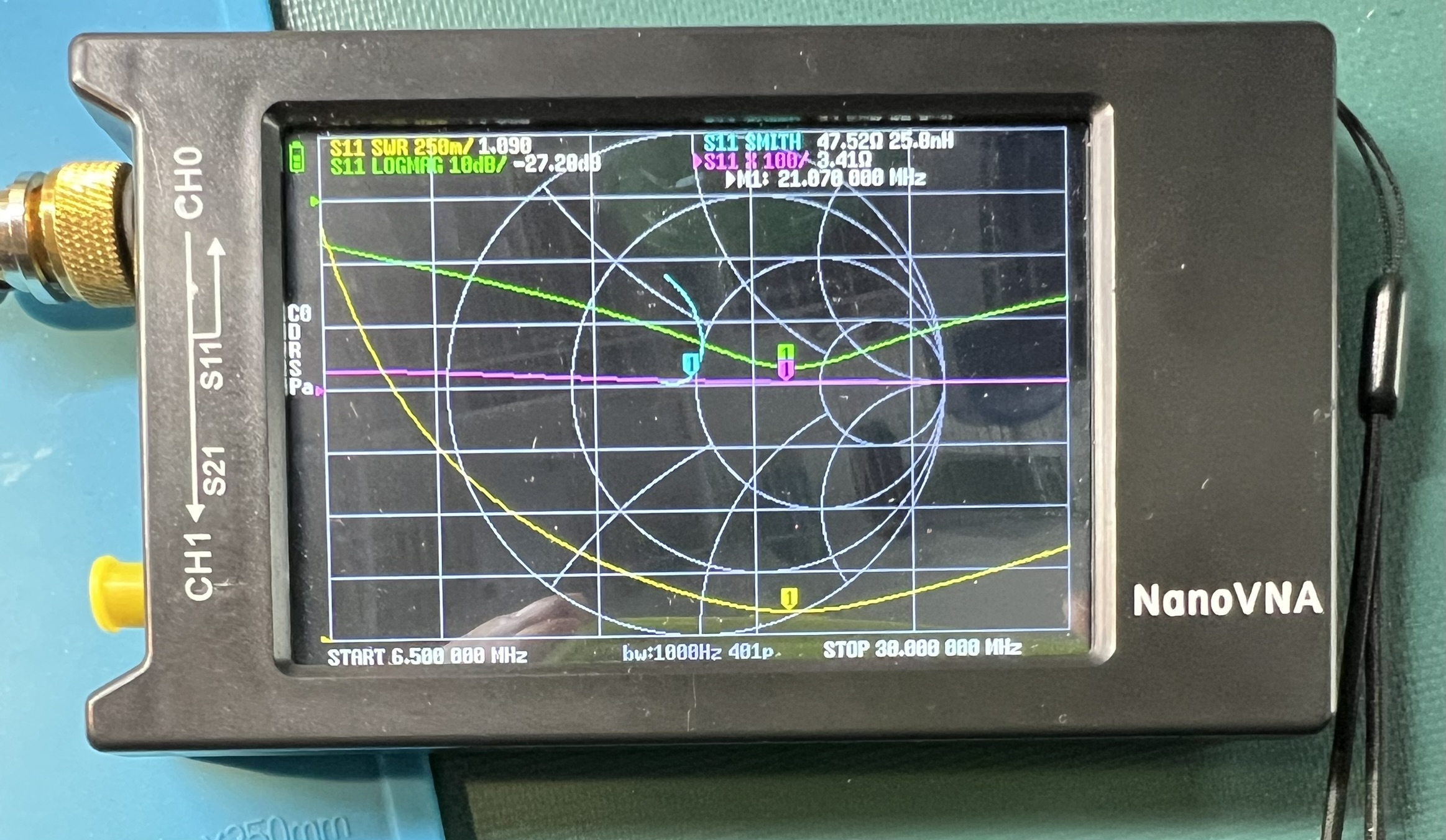

- Check the transformer with a nanoVNA and 450 Ohm resistor.